hot fix strass flatback Rhinestone swainstone

Swainstone ---- once meet never separate

SWAINSTONE is one of the TOP 10 famous brands in RHINESTONE industry, it has reliable quality guarantee, unbelievably strong back glue and wonderful cutting facet .

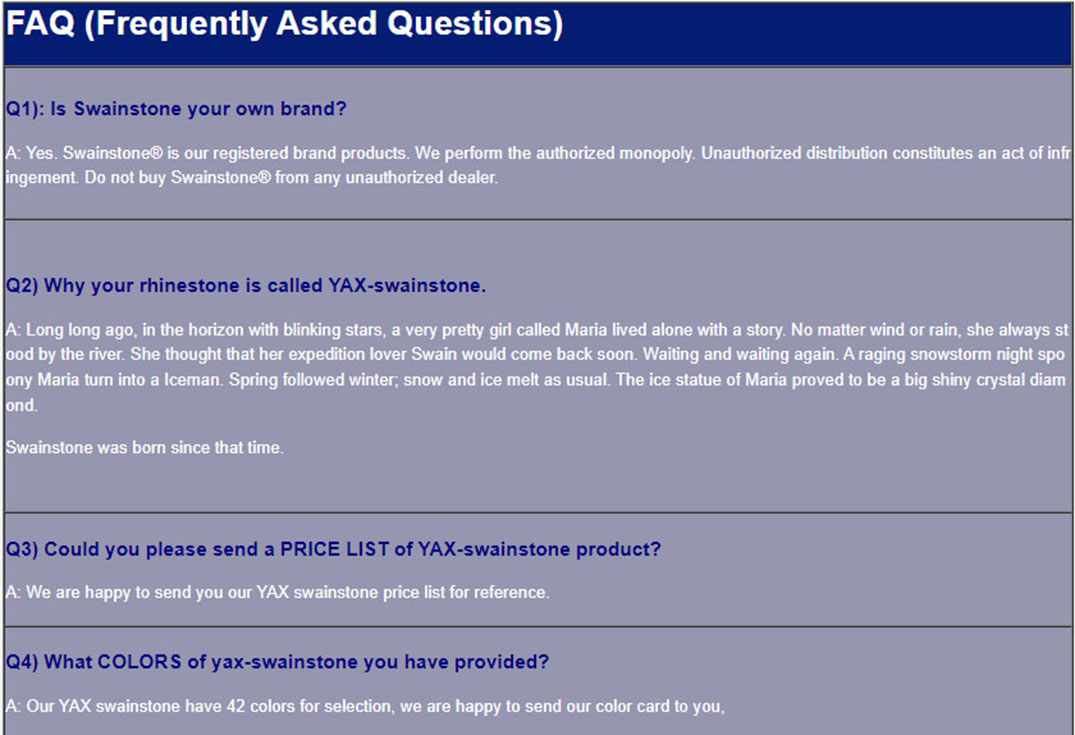

Once upon a time, in a place, far away, with twinkling stars, a girl called Maria who was very pretty, lived there. Every day no matter windy or rainy, she went to a river side to wait for her expedition lover, Swain, because she thought he would be back one day. One winter night, during a huge snowstorm, spoony Maria was turned to an iceman. Until the spring snow and ice melt, the ice statue of Maria was transformed to a big shiny crystal diamond. Since that, Swainstone was born in the world.

Ask Question About Product

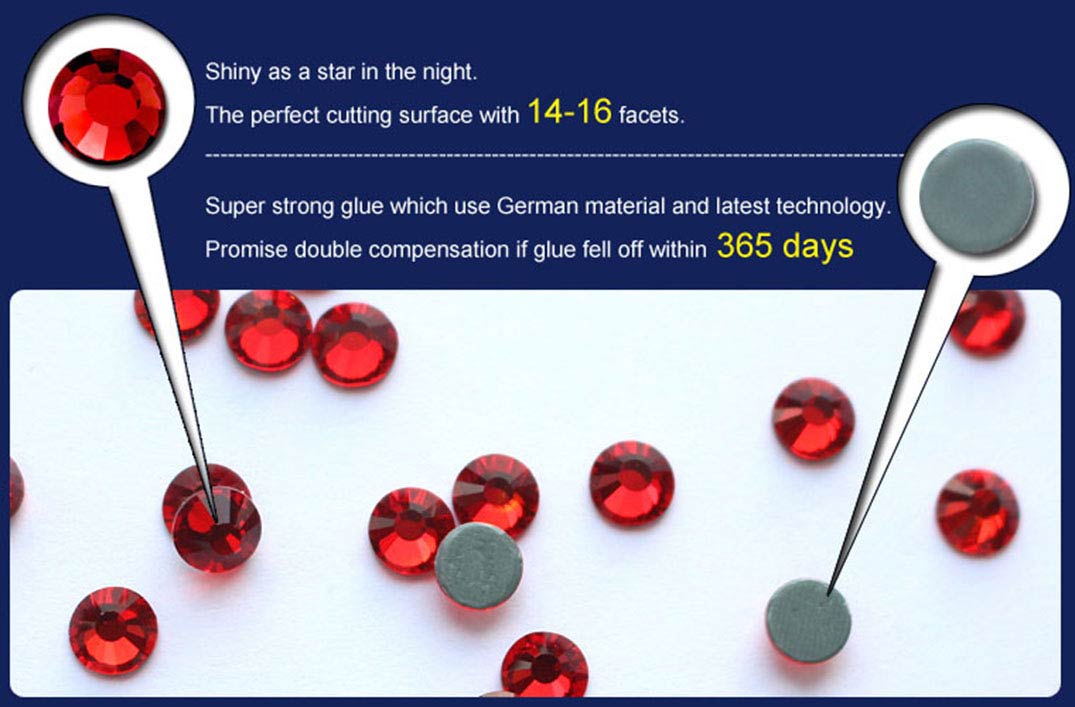

1. Quality Judgment Criteria:

(1) Number of facets: SS4~SS12: 8~10 facets; SS16~SS30: 12~16 facets.

(2) Facet craftsmanship: Facets include top small facets and bottom large facets. Facets should be flat without distortion, with sharp edges on side facets. Count facets as they determine crystal light refraction.

(3) Bottom circular polishing: Smooth finish without burrs; bottom circle maintains shape without oval deformation.

(4) Crystal quality: Clear transparency, no cracks, scratches, or bubbles. Clear crystals should have no dark spots; colored crystals should be free of impurities.

(5) Light refraction: Should refract sparkling light under spotlights. Visible light refraction when moving light source.

(6) Adhesive base appearance: Flat base without obvious overflow or protrusions.

All criteria can be verified through visual inspection.

2. Adhesive Base Testing Methods:

(1) Direct ironing. After complete cooling, scrape with ruler, rub by hand, lightly pick with fingernail.

(2) Place in container, shake vigorously when sealed. Separation of base from crystal indicates failure.

(3) Use sharp tools (needle, scraper) to attempt separation. Complete detachment indicates failure.

1. Industry Pain Points and Challenges:

(1) Using low-quality glass to imitate artificial crystal. Inferior glass cannot be polished or cut to achieve smooth surfaces and precise edges. Substandard hot melt adhesive powder and paint lead to aging and peeling over time.

(2) Outdated equipment and technology: Obsolete machinery and backward techniques make it impossible to achieve precise cutting and polishing, even with high-quality raw materials.

(3) Lack of integrity and substitution of inferior products: Promises of using premium materials are broken by switching to unqualified alternatives during production. Packaging quantities are manipulated to deceive customers with superficially low prices.

2. Solutions:

(1) We use high-quality artificial crystal, paint, and hot melt adhesive powder that exceed industry standards to ensure product excellence.

(2) Our cutting and polishing equipment is the latest generation of machinery, capable of delivering precision craftsmanship.

(3) We publicly disclose quality inspection standards and methodologies. We treat quality as the lifeblood of our enterprise and integrity as our core value, ensuring transparent packaging quantities and pricing.